Haulage operators were quick to realize the advantages offered by the Scammell automatic trailer coupling system and the use of articulated semi-trailers. Bedford (OSS model). Austin, Morris and Karrier were the most popular, but other makers chassis could also be fitted with the coupling including Thornycroft, Dennis, Seddon, Dodge, and Ford. The four-wheeled tractor units were mainly used on town-to-town haulage work leaving the three-wheeled Mechanical Horses to take the trailers on local and town deliveries. The Scammell coupling continued in regular use until the 1970s when the increasing gross train weights and the increased use of the fifth wheel coupling, caused it to fall out of favour with haulage operators. The Ministry of Defence and one or two small companies continued to use the Scammell coupling gear until the late 1980’s and it was believed that these were the last commercial users.

The Vehicle

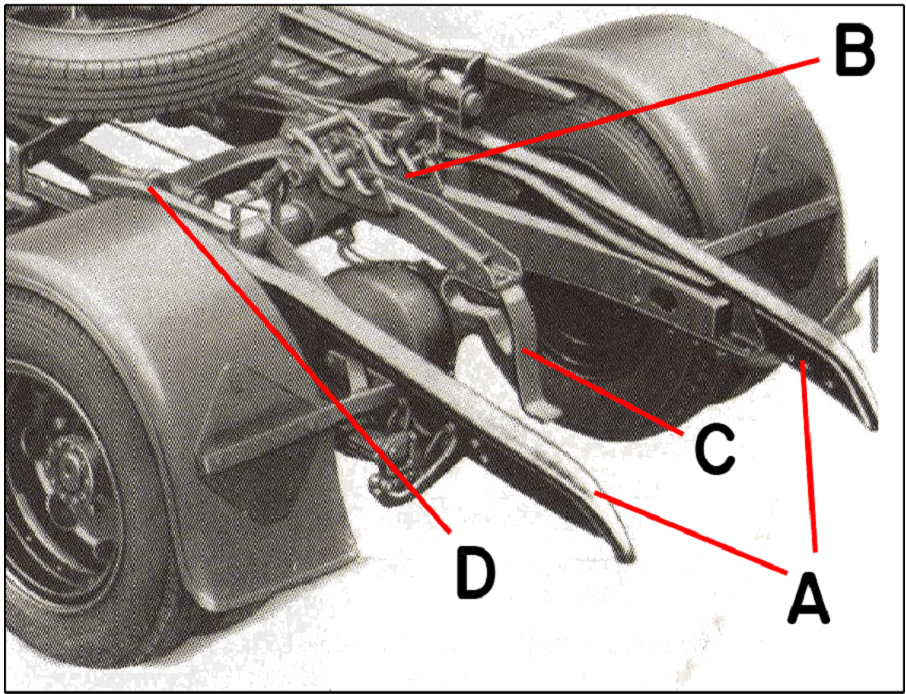

The vehicle part of the coupling consists of two ramps (A) attached to the rear of the chassis

Coupling hooks (B) are situated in front of the rear wheels.

Between the wheels is a S shaped striker (C) that acts on the Trailer undercarriage.

At the end of the ramp there are two buffers (D) to stop the trailer going too far and to lock the trailer against the coupling hooks

The Trailer

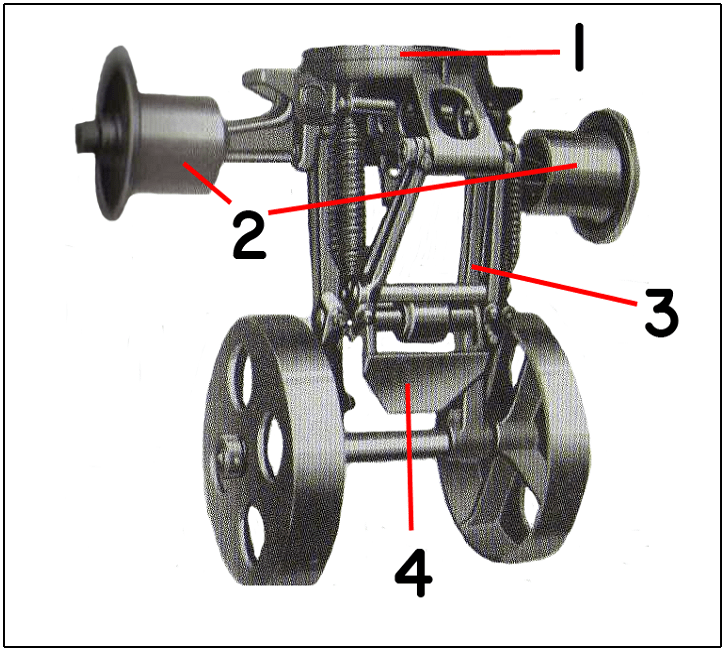

The trailer has an undercarriage mounted below a turntable (1)

With two rollers (2).

Under the beam holding the rollers a narrow twin legged frame (3) (with jockey wheels at its extremities)

A release plate (4) is situated between the wheels. The legs and wheels folded back when the release plate is actuated by a vehicle.

How it works

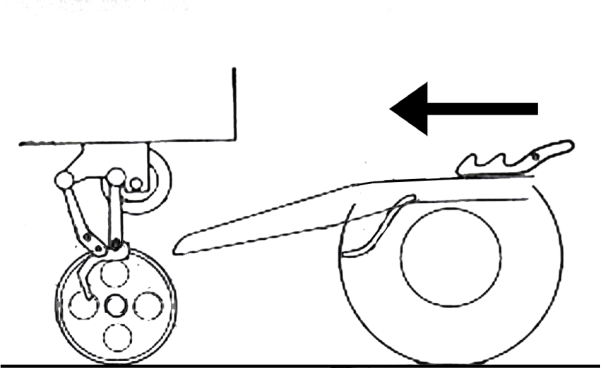

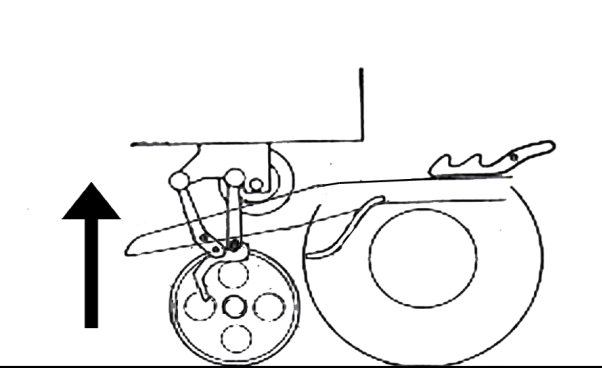

The vehicle is reversed towards the trailer. Its ramps lined up with the trailers rollers.

The vehicle ramps raise the trailer off the ground

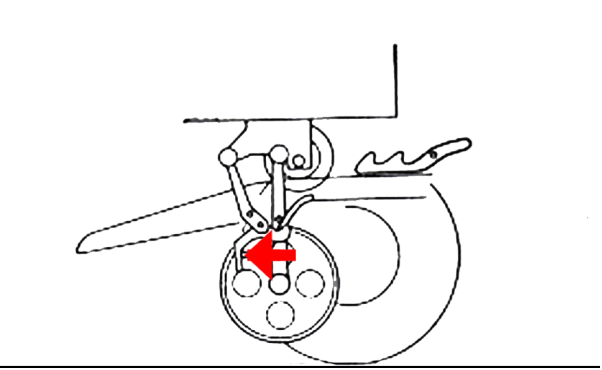

The trailer continues to roll up the vehicle ramps until the trailer release plate hits the vehicles striker.

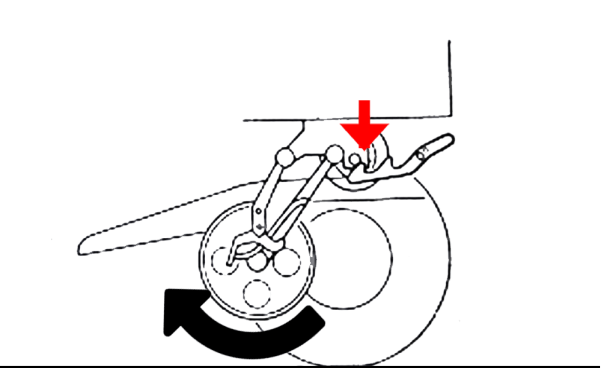

The trailer legs then follow the vehicles S shape striker folding the legs back, as the trailers roller beam engages with the vehicles coupling hook

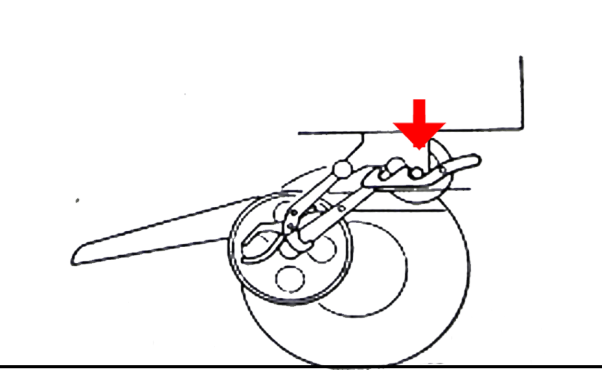

The trailer rollers reach the vehicles ramp buffers and the roller beam engages with the second notch of the vehicles coupling hook, securing the trailer in place.

Most importantly the trailer brake and trailer light connections were made automatically and all the driver had to do was release the trailer hand brake and connect the registration plate to the rear of the trailer.

The turntable allows over 180° of rotation allowing the vehicle to be extremely manoeuvrable for operating in tight yards and depots.

Details of Trailers can be found Here