3 Ton Townsman Mechanical Horse

ENGINE

Standard O.E. 160 high speed diesel.

4 Cylinder, 3-91/200″ bore by 4-1/4″ stroke. 2,610 cc.

Compression Ratio: 21.5:1

B.H.P. 62 at 3000 rpm

Max torque: 123 lb.ft at 2000 rpm

ENGINE AUXILIARIES

Fan: belt driven from front end of crankshaft

Water pump: belt driven centrifugal type

Fuel injection: D.P.A distributor type pump with mechanical governor

Air Cleaner: large oil bath type cleaner outside bonnet.

CLUTCH

Borg and Beck 10″ diameter single plate, hydraulically operated

GEAR BOX

Four forward and one reverse speed with remote control and dog engagement.

Ratios

1st 6.3:1

2nd 3.0:1

3rd 1.68:1

4th 1:1

Rev 8.4:1

DRIVING AXLE

Single bevel reduction fully floating type. Hubs, roller bearings and stubs are interchangeable with carrier. Four pinion differential mounted on ball bearings

Overall Ratio

5.625:1

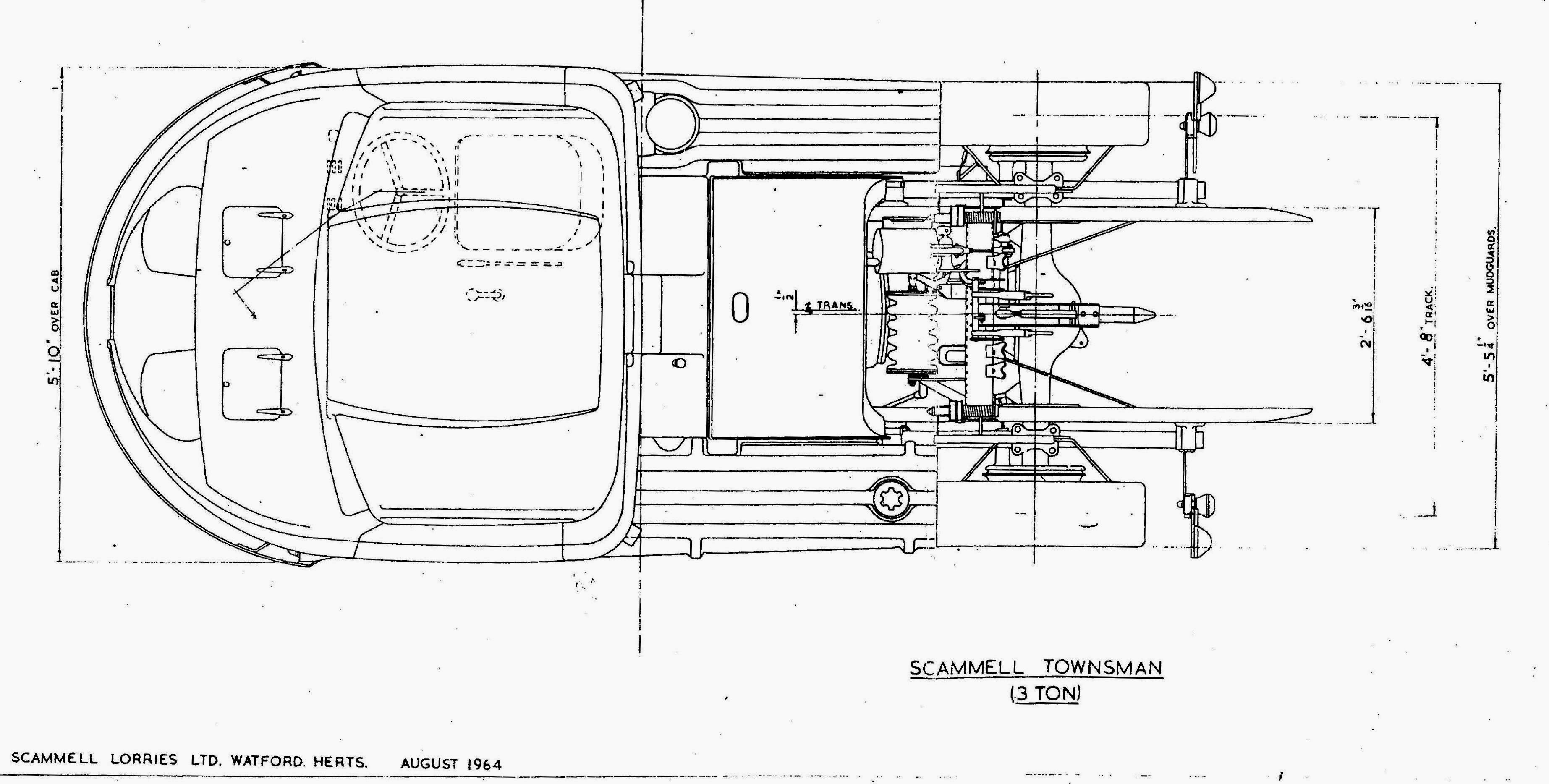

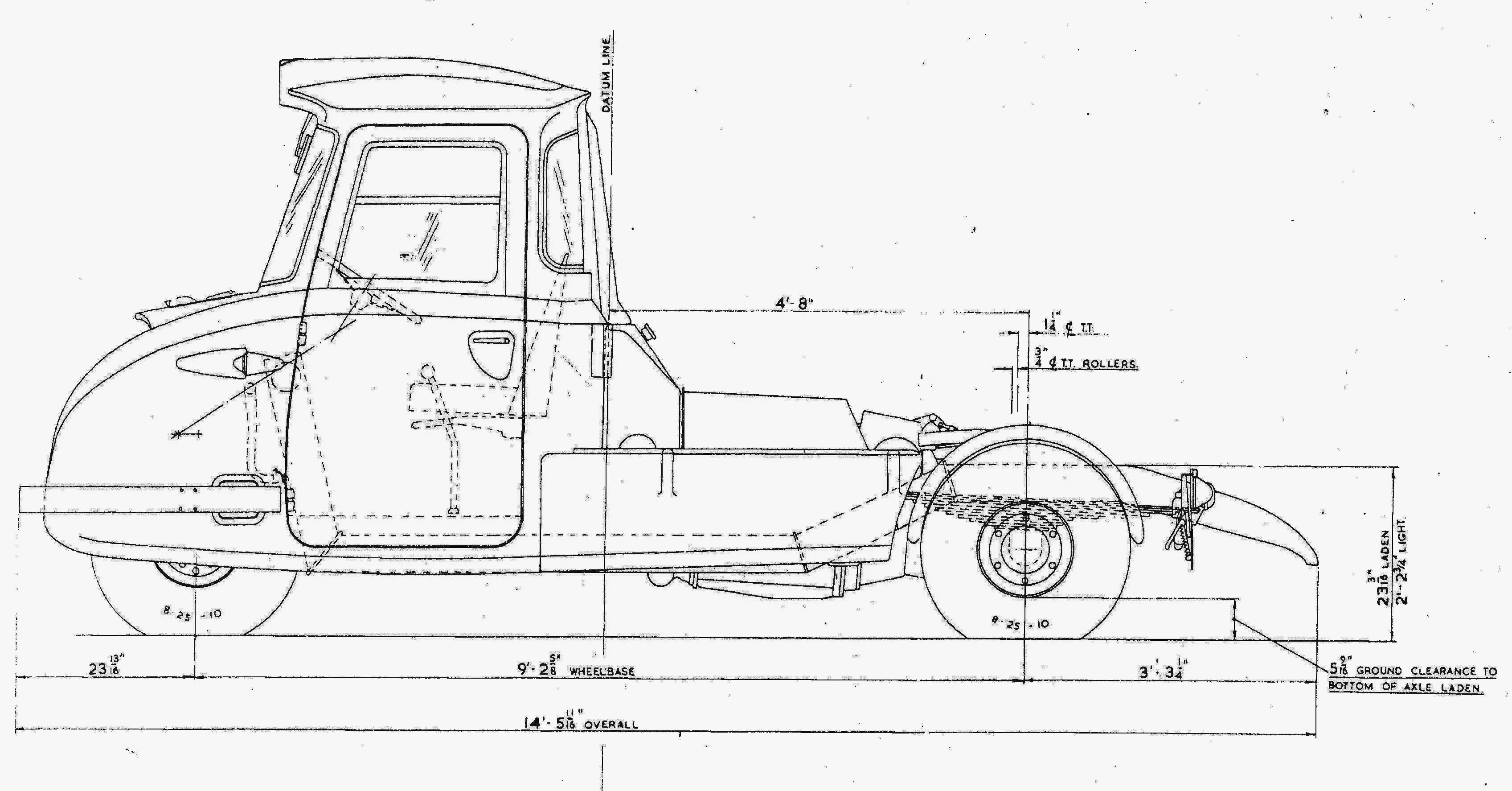

TRANSMISSION

Engine, clutch housing, gearbox and driving axle are built into one unit and pivoted at the front of the engine on a large rubber bush.

FUEL TANK

14-gallons capacity.

BRAKES

12″ diameter x 2-1/2″ wide brakes are hydraulically operated and fitted on the driving axle only. They are vacuum servo assisted. The foot pedal gives power braking to the tractor and trailer wheels. A small hand lever to the right of the driver’s seat gives power braking to the trailer wheels only. Also a ratchet type hand operated parking brake to the left of the driver’s seat provides direct mechanical braking to the driving axle.

Braking performance laden: 50% Tapley at not more than 100lbs pedal pressure.

SPRINGS (Driving Axle)

Two-rate rear springs giving a good ride both light and laden.

RADIATOR

Morris Block type radiator is rubber mounted behind the cab and can be removed without lifting the cab shell. The cooling system incorporates a plastic expansion tank to provide a “no loss” system.

STEERING

A 17″ steering wheel is mounted on a bearing bracket in the cab construction, complete with self lubricating bushes and provision for the fitting of a WASO steering lock. Universal joints transmit torque to steering box, which is an oil bath unit with worm and wheel gearing giving a ration of 17:1. Upward thrust from the front wheel is taken on a ball thrust race. Sideways loads are taken on a robust needle roller race positioned under the worm wheel assembly.

CAB

The cab is of glass fibre reinforced plastic and is made in two parts. The base incorporates the cab to chassis mountings, the instrument panel, steering wheel, hand and foot controls, driver’s seat assembly, provision for mate’s seat, battery mountings and ducting for fresh air supply. The outer shell is attached to the base and located by moulded registers which guarantee interchangeability. Incorporated in the shell are the doors, windows, and ducting for air to radiator, drawing air through intake at top of windscreen and thence over centre section of roof and down back of cab to front of radiator block. Rear view windows are situated either side of duct with wrap-round corners. The curved windscreen is in one piece. All windows are of generous proportions and made of toughened glass. The doors have drop windows and recessed handles with key type slam locks capable of being locked from the inside, the same key to fit the engine switch. The drop windows can be locked from the inside in the closed position. Grab lips are provided on the inside of each door.

Head and side lamps are mounted in the cab shell and provision is made for screen washers and flashing indicator lamps in case these are required at a later date. A ventilator is provided in the air duct in the roof. The rear corners of the cab are protected from damage if contact is made with the carrier by large black rubber buffers which are incorporated in the rear corners.

Inside the cab a dip-stick clip, coat hook and wire mesh document box are provided together with a shelf with raised front edge for the driver’s personal effects. A heater and demister is fitted and also twin “Desmo” convex rear mirrors (Type No.402). The hand brake lever is positioned so as not to impede the driver when using the near-side door for entry or exit to the cab and the driver’s seat support is arranged to cause the minimum obstruction to the floor. A detachable mate’s seat is optional.

An interior sun visor is provided above the windscreen in front of the driver. The cab can be colour impregnated if required.

FRONT SUSPENSION

Coil spring totally enclosed and immersed in oil, spring movements damped hydraulically. Movement of wheel transmitted to the spring by means of a stamped steel crank.

FRAME

Of all welded construction, including integral ramps, the frame is made from pressed steel channel section with channel crossmembers at the rear and tubular members of robust proportions at the front. The front crossmember carries a mounting bracket for the steering assembly and particular attention has been paid to the elimination of points which may form a trap for mud. The whole frame is phosphated before painting.

COUPLING GEAR

Scammell 3-ton automatic gear with ramps integral with the chassis frame and power operated release mechanism. The coupling gear warning light switch is controlled by the hooks.

CONTROLS

The steering wheel is mounted on the cab base assembly and the clutch pedal, foot brake and accelerator, together with the hydraulic cylinders, are mounted on a fore and aft sliding unit attached to the base assembly.

Hand brake and gear change levers are positioned to the left of the driver’s seat. The coupling release lever is mounted on the back of the cab and the power hand brake for the trailer axle is on the right of the driver’s seat.

ELECTRICAL EQUIPMENT

12-volt positive earth system.

INSTRUMENTS

Speedometer, 0-60mph with distance recorder.

WARNING LIGHTS

These have a minimum diameter of 1/2″ except the headlamp warning light, dynamo warning light and flashing indicator warning light (if fitted). Labels are provided to identify the lights and the colours are as follows:

Coupling warning: Red

Engine oil warning: Red

Vacuum warning: Red

Dynamo warning: Orange

Headlamp warning: Orange

LAMPS

2 Headlamps (pre-focus type preferred)

2 Forward facing side lamps

2 Detachable tail and stop lamp assemblies

1 Cab interior light

SWITCHES

The hand controlled headlamp dipper switch and the horn button are grouped below the steering wheel and the instrument panel light switch is wired in circuit with the side lamps. The cab interior light has its own switch.

TYRES

8-1/4″ x 10″ by 10 ply rating single tyres fitted on 5″ base two-piece wheels.

TOWING ATTACHMENT

The attachment is situated centrally, high up between the headlamps behind a removable panel and is intended for use with a towing bar.

FRONT BUMPER

The bumper bar extends the full width of the cab and is carried round the sides to a point just ahead of the front door pillar so providing maximum protection for the cab.

JACKING PAD

A suitable pad is fitted adjacent to the front wheel so that the frame can be raised for wheel removal.

TARPAULIN

Provision is made for carrying a tarpaulin on top of the fuel tank with four 3/8″ diameter eyes suitably positioned for lashing down with rope.

OPTIONAL EXTRAS

Roof mounted flashing indicators can be fitted when required without structural alteration to the cab. The same applies to screen washing equipment.

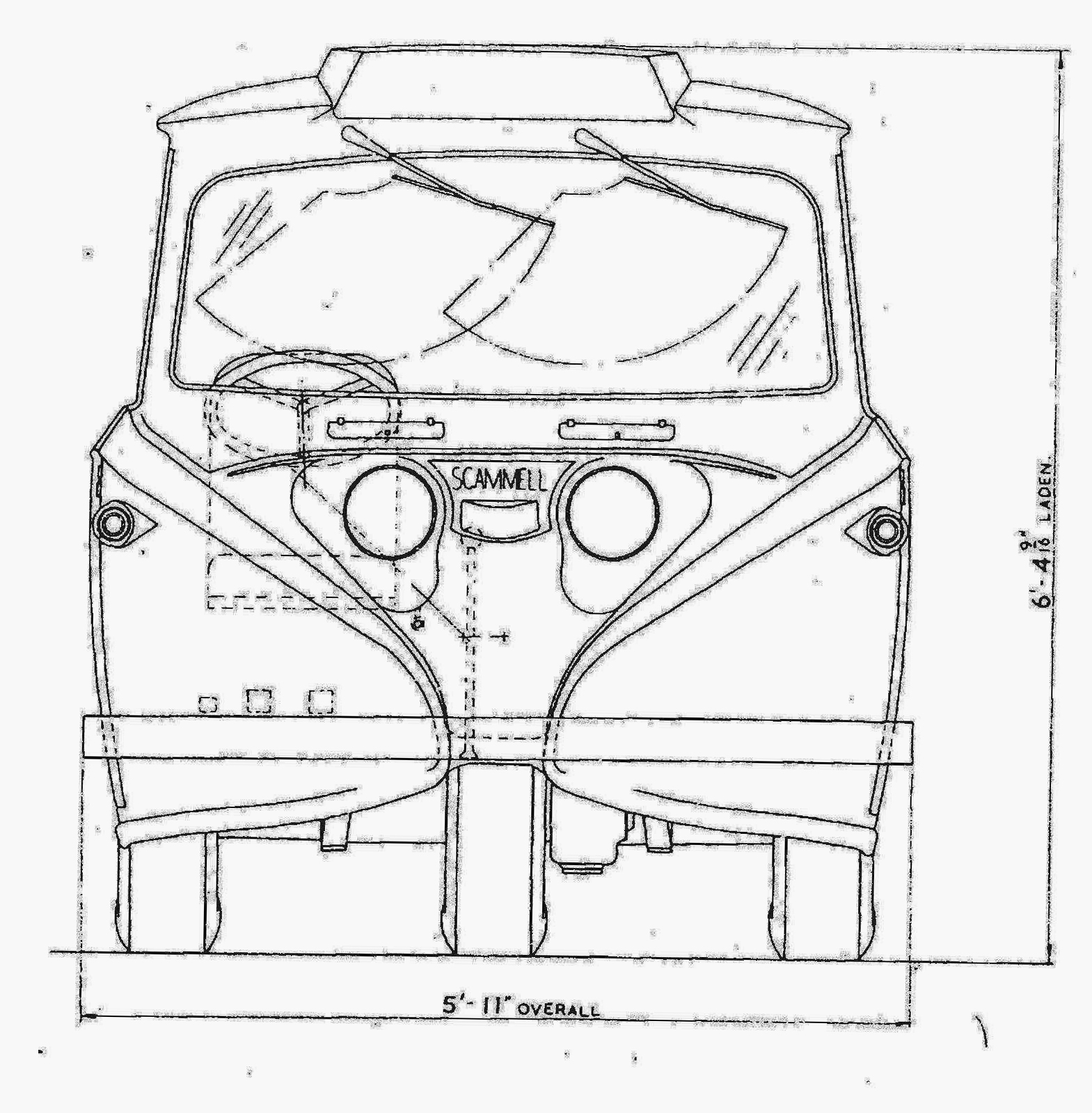

DIMENTIONS

Overall Height – 76″

Overall Length – 173-11/16″

Overall Width – 70″

Wheelbase – 110-5/8″

Track – 56″

Minimum Ground Clearance – 5-9/16″

Centre line of axle to back of cab – 56″